Used Oil Analysis Testing - Particle Counting

Automatic Particle Counting in Used Oil Analysis

Critical machinery are the backbone of industrial operations. The efficiency, longevity, and reliability of these systems heavily depends on the quality and condition of the lubricants used. As such, used oil analysis emerges as a crucial aspect of ensuring optimal machine performance. Over the next month we will write describe different tests in our industrial slate of laboratory oil analysis. This discussion will break the testing into three broad categories, routine, advanced and exception.

Routine Testing

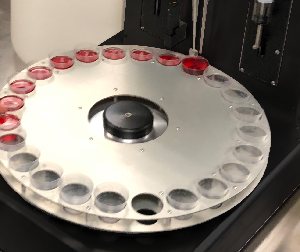

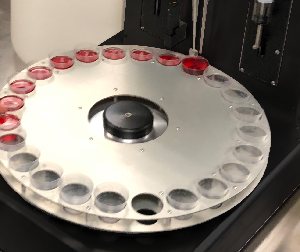

Routine testing of an in-service lubricant has a laboratory test package that is performed on a predetermined time interval typically at every one to three months. These tests monitor for equipment wear, oil contamination, and oil condition. MRT Laboratories' STLE and ICML certified professionals can help you determine the optimal testing to fit the needs of your unique equipment and operations. In this blog we discuss automatic particle counting to measure fluid cleanliness, since we receive the most customer questions about this portion of the industrial testing slate. Thank you, CiNRG for providing a photo of their CINRG CS-APC-22M particle counting system, which is our primary particle counting instrument (https://www.cinrg.com/).

Automatic Particle Counting (APC) is a widely used technique for measuring the number and size distribution of particles in a fluid. It is a common test used in used oil analysis to monitor the condition of the oil and to identify potential problems with the equipment in which it is used. Automatic particle counting methods can be categorized into two main types: optical and non-optical.

Optical Particle Counting

Optical particle counting utilizes light to detect and count particles suspended in a fluid. A sample of the fluid is passed through a light beam, and the light scattered by the particles is detected by a sensor. The size of the particles is determined by the angle at which the light is scattered.

Particle Counting by Pore Blockage

Particle counting by pore blockage, also known as the pore blockage method, is a technique for measuring the number and size distribution of particles in a fluid. It is a widely used method for determining the cleanliness of fluids, particularly in hydraulic and lubrication systems.

The pore blockage method involves passing a known volume of fluid through a calibrated filter membrane with a defined pore size. Particles larger than the pore size are trapped on the membrane, while smaller particles pass through. The pressure drop across the membrane is measured as a function of time. As more particles are trapped on the membrane, the pressure drop increases. The pressure drop data is then used to calculate the number and size distribution of particles in the fluid using a mathematical model that relates the pressure drop to the particle size and concentration.

Particle Dilution to Reduce Interference

To reduce interference and improve the accuracy of particle count measurements, particle dilution is often employed. This involves diluting the fluid sample with a clean solvent, which will dissolve bubbles and also microscopic spent additive material that typically cannot be filtered from the oil with a traditional filtration capture method.

Conclusion

APC is a valuable technique for assessing fluid cleanliness and monitoring equipment health. Optical and non-optical methods, including particle counting by pore blockage, each offer unique advantages and limitations, making them suitable for different applications. Precisely applied sample dilution can effectively reduce interference and enhance the accuracy of particle count measurements by conditioning the fluid for an optimal view of the sample stream by the optical laser.