Methods for Determining Abnormal Oil Analysis Test Results

Statistical Comparison, Rate of Change, and Lock-Step Approach

Each type of mechanical rotating equipment can have different lubrication regimes, lubricant requirements, and wear modes. Analyzing used oil analysis is common preventive maintenance worldwide, although interpreting oil analysis results can often be confusing without training. How do trained analysts at commercial oil analysis laboratories decide which test results warrant further monitoring, additional (exception) testing, inspection, or corrective action?

There are several methods of determining which test results indicate a potential problem, statistical comparison, rate of change, or a lock-step approach. A statistical comparison is the most widely employed methodology. Monitoring the rate of change (RoC) is employed when there is not a well-behaved normal (Gaussian) distribution of the data over time. The lock-step approach is useful for determining cause and effect.

Statistical Methodology

A statistical approach works well when the data follows a standard bell curve, as seen in Figure 1 below. Viscosity measurements are a great example of a symmetrical (two-sided) curve. Viscosity can be low due to fuel dilution, process contamination, viscosity index (VI) improver shearing, or mixture with a lower viscosity lubricant. The viscosity may increase due to oxidation, fuel soot, or mixture of a higher viscosity lubricant.

In a Gaussian distribution, density, on the y-axis, tells us how likely are the different test results. Imagine a bell-shaped curve. The top of the curve is where the most common values are, and as you move away from the top, the values become less common. Density helps us understand where most of the values in a dataset are concentrated and how they spread out around the average.

Figure 1

Data may be skewed to the right or left. Figure 2 is a graph of iron values, which is skewed to the right. This is an example of data where we are primarily concerned when the data exceeds a specified limit.

Figure 2

Statistical limits, although they have limitations, are a useful tool for setting alarm limits in oil analysis testing. These limits can be modified based on feedback from plant personnel. OEMs often require oil analysis and provide guidelines for limits on fluid condition, wear, and contamination. It is important that the OEM guidelines are followed, especially if the equipment is within the warranty period.

While statistical methods provide valuable insights, they should be complemented with expert judgment, qualitative analysis, and real-time monitoring to ensure a comprehensive understanding of machinery reliability and oil condition. Combining statistical analysis with a holistic approach helps address the limitations and improve overall predictive maintenance strategies.

Cumulative Trends and Rate of Change (RoC)

In a splash lubrication gearbox without oil circulation or filtration there can be a steady increase in particles or wear metals over time. Figure 3 below, shows a steady increase in iron concentration (measured in ppm) in a 12-month period. This increase occurs because there is no filtration system in place to remove wear particles from the oil.

Figure 3

At first glance the increase in iron debris per month looks steady, although the rate of change from month 11 to month 12 is substantial and should be flagged abnormal. Let’s look at the same data plotting the iron (ppm)/month (Fig. 4). Viewing the data in this format makes it obvious that the increase is about 3x that of the previous samples during this final recorded period.

Figure 4

"What is the cause of this increase?" Utilizing lock-step trending can assist the investigation.

Lock Step Trending

We investigate other changes that might be trending upward along with the iron. In this particular case, silicon and aluminum are also increasing.

Figure 5

A graph of the data (Figure 5). Reveals that increases in the three elements appear to positively correlate. Increasing silicon can be dirt contamination, but also anti-foaming additives, coolant leak, leaching of silicon sealants and gaskets or manufacturing residue. Dirt often has a silicon-to-aluminum ratio around 4:1. In this oil analysis case the ratio of silicon to aluminum is consistent and both metals are increasing over time. Therefore, abrasive dirt contamination is a defensible cause of the accelerated iron contamination which warrants further near-term investigation.

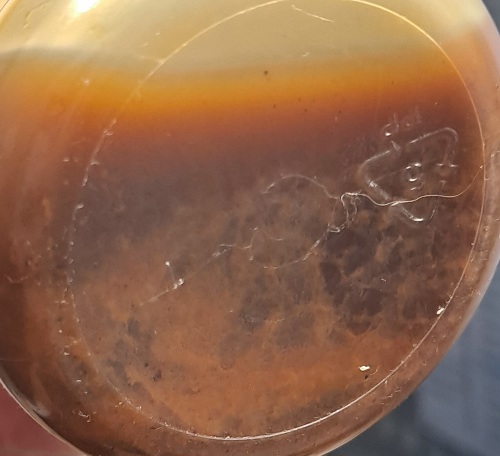

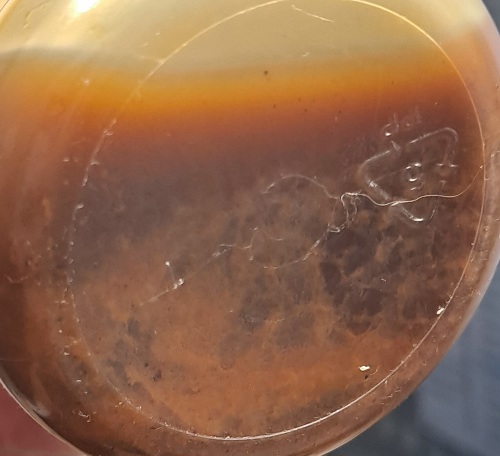

Taking this a step further, if Chromium is also present and increasing, this would lead us to conclude that bearing wear is occurring since chromium is commonly found in steel alloys used for bearings. Microscopic analysis of this sample is ideal in this situation. Dirt is easy to see under the microscope and abrasive debris should be prevalent and quickly identifiable in this case.