Beyond Just Numbers on a Page: Lockstep Trending Tells a Deeper Story

Data Trends are Key to Successful Oil Analysis Testing

Overview

Lockstep trends in oil analysis are changes in multiple test results that occur simultaneously in a coordinated fashion. As an example, elements such as iron, copper, and tin, can rise or fall at the same time. Their synchronous movement offers more pinpointed possibilities of issues with the oil or the equipment.

Introduction

Why use lockstep trending? There is a set of alarm limits for each test result on your oil analysis reports. These alarm level thresholds, whether set statistically or provided by the OEM, offer critical guidance for maintenance. However, the alarms may not detect a developing problem until it is already too late. By incorporating trend analysis, we detect potential issues much earlier, providing an opportunity to correct a problem before it becomes more time-consuming and costly to repair, reducing downtime and protecting your bottom line.

Common Lockstep Trending Scenarios

Case 1: Dirt Ingression

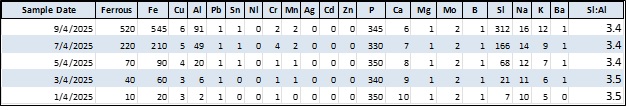

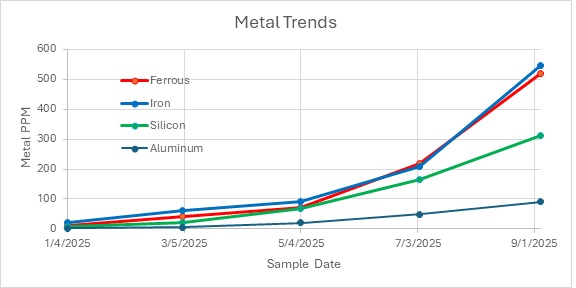

Silicon can come from anti-foaming additives or silicone sealants. It often signals dirt ingression. How can we determine whether an increase in silicon is caused from dirt? Utilizing lockstep trending with other elements is key. Dirt typically contains aluminum in addition to silicon, with a Si:Al ratio of about 3:1 to 4.5:1. In Table 1 and in Figure 1, notice the lockstep trend of silicon and aluminum increasing over time. As the data shows, the aluminum is increasing in lockstep with the silicon and iron, providing strong evidence of abrasive wear due to dirt ingression. This trend offers an early warning to check the air intake systems and filters before the abrasive particles cause serious component damage.

Table 1

Figure 1

Case 2: A Hydraulic Oil Sample Contaminated with Engine Oil

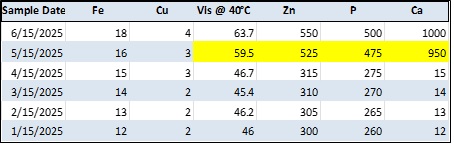

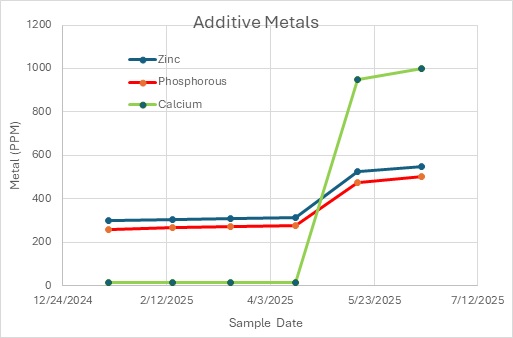

Table 2 and Figure 2 show oil analysis testing results for an in-service AW 46 hydraulic fluid. Notice that over time, wear metal element levels are stable, although samples from May and June show an increase in oil additives and the viscosity a 40C. The increase in Zinc (Zn), Phosphorus (P), and especially Calcium (Ca) is a clear lockstep trend. This simultaneous increase in additive metals, combined with a corresponding increase in viscosity, strongly suggests that a different oil, likely a high-detergent engine oil, was accidentally added to the unit.

Table 2

Figure 2

This lockstep trend provides an immediate and undeniable signal that the wrong fluid has been added to the system, allowing you to act, such as an immediate fluid change, filter change and system flush, before the contamination leads to seal damage and accelerated wear.

Case 3: Coolant Contamination in Oil

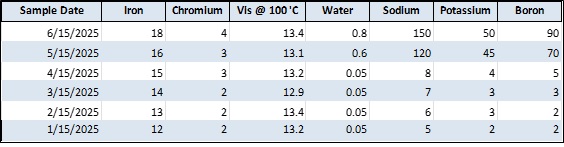

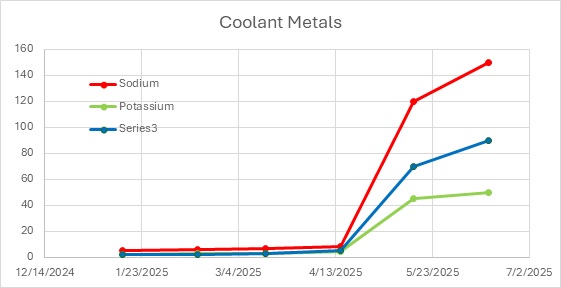

Our final example is a clear and powerful illustration of how a lockstep trend can save a machine from catastrophic failure. In Table 3 and Figure 3 below, the baseline data from January to April show a healthy system with stable levels of wear metals, correct viscosity, and minimal coolant-related elements. However, the samples from May and June detect a dramatic and synchronized lockstep increase in the levels of Sodium (Na), Potassium (K), Boron (B), and Water (H₂O).

Table 3

Figure 3

This unmistakable trend points directly to coolant ingression. The simultaneous spike in these specific elements, which are not typical oil additives, combined with a sudden increase in water content, provides a powerful and immediate diagnosis. This allows the maintenance teams to bypass other possibilities and address the root cause, a coolant leak, before it causes catastrophic damage to bearings, seals, and other critical components.

In Summary

Oil analysis provides crucial insights into the health of your equipment, but relying solely on individual testing alarm limits can be like waiting for a fever to confirm an infection. Lockstep trending goes a step further, allowing you to see problems as they develop before they become critical.

As we have seen in the examples of dirt ingression, cross-contamination, and a coolant leak, a synchronized rise or fall in multiple elements tells a deeper, more accurate story. By looking beyond, a single alarm and analyzing how elements move together, you can:

· Detect Issues Earlier: Spot subtle changes in data that would not trigger an alarm on their own.

· Diagnose the Root Cause Quickly: The lockstep signature points directly to the source of the problem, saving time and resources on troubleshooting.

· Prevent Costly Damage: Correcting a problem based on a trend is far less expensive than repairing equipment after a catastrophic failure.

Conclusion: Go Beyond the Numbers

Lockstep trending is not just a technical exercise; it is a powerful tool that transforms your oil analysis program from reactive to proactive. It empowers you to interpret the story your data is telling, enabling you to make informed maintenance decisions that extend equipment life, reduce downtime, and protect your bottom line. By incorporating this technique, you can unlock a new level of predictive maintenance and ensure your assets run at peak performance. Ready to unlock more insights from your data? Contact the lab today and speak with one of our ICML- or STLE-certified analysts. We will help you interpret your results, identify trends, and turn your oil analysis program into a powerful predictive maintenance tool.