Lubrication's Arch Enemy: Water Contamination

For maintenance and reliability professionals, understanding water contamination is not just optional, it's FUNDAMENTAL

Water is one of the most destructive contaminants in a lubrication system, directly compromising machine reliability and lubricant health. Effective contamination control is a cornerstone of any world-class lubrication program. This guide breaks down water contamination into the core concepts you need to know, from its impact on components to the proactive strategies required to manage it.

The Impact of Water on Machine Reliability

When water contaminates a lubricant, it initiates a cascade of destructive chemical and physical processes. For a reliability professional, understanding why water is so damaging is key.

Additive Depletion & Hydrolysis: Water chemically attacks and breaks down critical additives. This process, known as hydrolysis, is particularly aggressive with additives like anti-wear (AW) and extreme pressure (EP) agents. It can also break down certain synthetic base oils, like esters.

Accelerated Oil Oxidation: Water, in the presence of heat and metal catalysts (like copper or iron particles), dramatically accelerates the oil's oxidation rate. This leads to premature oil degradation, sludge, varnish formation, and a shortened lubricant life.

Reduced Lubricant Film Strength: Water has a much lower viscosity than oil. When emulsified, it displaces the oil film, reducing the load-bearing capacity between two moving surfaces. This leads to metal-to-metal contact, scuffing, and adhesive wear.

Bearing Damage (Hydrogen Embrittlement): In rolling element bearings, the extreme pressures in the load zone can cause water to flash to steam. This can liberate hydrogen atoms, which are then absorbed into the bearing's metal structure, causing hydrogen embrittlement and leading to subsurface cracking and spalling.

Corrosion and Rust: Free water settles on machine surfaces, causing simple but destructive rust. These rust particles then break free, circulate through the system, and act as abrasive catalysts, accelerating wear even further.

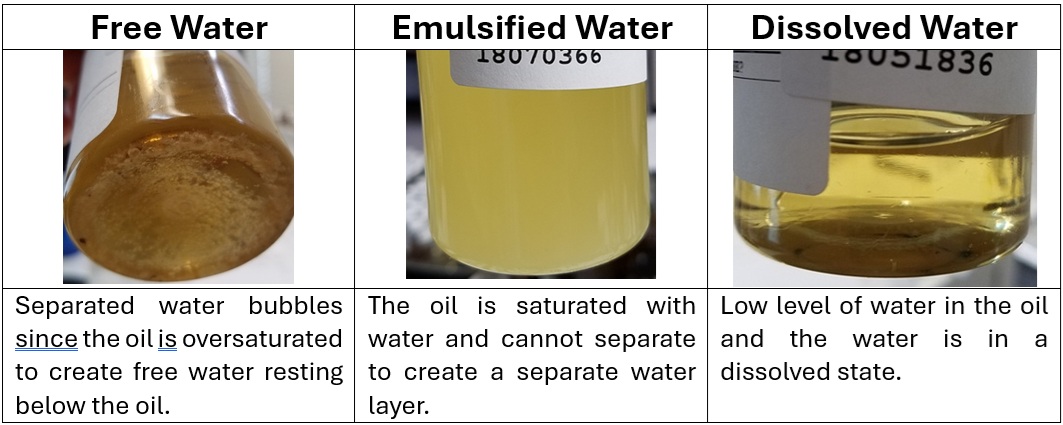

Identification: The Three Forms of Water

Water exists in three distinct states in oil. The state determines both the threat level and the removal method.

1. Dissolved Water:

- What it is: Individual water molecules are dispersed and dissolved within the oil. The oil will still appear bright and clear.

- The Problem: All oil has a saturation point, which is the limit to how much water it can hold in this dissolved state. This point varies significantly with oil type, age, and fluid temperature (hotter oil holds more dissolved water). While not an immediate threat, it's the precursor to more dangerous forms.

2. Emulsified (Suspended) Water:

- What it is: Water contamination exceeds the saturation point of a lubricant, and microscopic water droplets are suspended in the oil, creating a milky, hazy, or cloudy appearance.

- The Problem: This is the most damaging form of water. The emulsion circulates with the oil, attacking all components, rapidly depleting additives, and drastically reducing film strength.

3. Free Water:

- What it is: The oil reaches 100% water saturation, and then additional water becomes separated from the oil and settles in bubbles or even a separate layer at the bottom of reservoirs and sumps.

- The Problem: Free water is the primary source of rust and provides a breeding ground for microbial growth. Agitation can easily re-entrain this water, turning it back into a destructive emulsion.

Sources of Ingression: A Contamination Control Checklist

A key task for any lube tech or reliability engineer is identifying and eliminating water's entry points.

1. Atmospheric Ingress:

- Humid Air: Most reservoirs breathe. As temperature changes, humid air is drawn in, and water condenses on the internal walls.

- Poorly Sealed Reservoirs: Worn gaskets, hatches, and fittings provide an easy path for moisture.

2. Operational & Process Ingress:

- High-Pressure Washdowns: This is a common maintenance-induced failure. High-pressure spray can force water past seals that are otherwise effective.

- Leaking Coolers & Heat Exchangers: A primary culprit for massive and sudden water contamination.

- Failing Seals: Worn or damaged seals on rotating shafts (pumps, gearboxes) are a common entry point.

3. Storage and Handling:

- Improper Drum Storage: Drums stored vertically outdoors will collect water on top, which is then drawn into the drum during thermal cycling.

- Best Drum Storage: Store drums indoors or, if outdoors, on their side with bungs at the 3 and 9 o'clock posit

- Improper Tote Storage: Totes have large, flat tops that can collect significant amounts of water. Their plastic construction can also degrade and become brittle over time UV (sunlight) exposure, compromising their integrity. Their vents are also an open path for humid air.

- Best Tote Storage: Indoor Storage is much better, especially for light-sensitive or hygroscopic (water-attracting) oils. Ensure all caps and valves are tightly sealed. If used for long-term storage or dispensing, fit the vent with a desiccant breather to protect the oil from atmospheric moisture.

Detection & Monitoring: The Role of Oil Analysis

You can't manage what you don't measure. A routine oil analysis program is your single best early warning system for water contamination.

- The Key Test: While a visual check or a "crackle test" can spot gross contamination, the industry-standard test for precise, quantitative measurement is the Karl Fischer Titration method (ASTM D6304). This test reports water content in Parts Per Million (PPM), allowing you to track even low-level dissolved water.

- Setting Alarms: Don't use a one-size-fits-all approach. Establish specific water alarm limits for each asset class. A critical turbine system may have a caution limit at 150 PPM, while a splash-lubricated gearbox might be set at 500 PPM.

- Correlating Data: Water is a "root cause." Always look for the "effects" in your oil analysis report. Correlate high water levels with:

- Rising Acid Number (AN): This signals accelerated oil oxidation.

- Contaminant metals: These metals provide a clue to the source of water ingression. Sodium, potassium, barium and other metals may come from coolant or process contamination.

- High Particle Counts: A spike in iron (Fe) or other wear metals often points to active corrosion and wear caused by the water

Remediation & Control: Proactive vs. Reactive Strategies

A world-class program focuses on proactive control, not just reactive removal.

Reactive (Removal) Techniques

- Gravity Separation (Drainage): The simplest method for free water. Requires regular, documented draining of reservoir low points.

- Centrifugation: Uses centrifugal force to separate fluids of different densities. Highly effective for removing large amounts of free and emulsified water.

- Vacuum Dehydration: The gold standard for critical assets (e.g., turbine or hydraulic systems). By applying heat and vacuum, this method lowers the boiling point of water, allowing it to be boiled off and removed as vapor. It is the only common method that effectively removes all three forms of water, including dissolved water, to bring oil back to specification.

Proactive (Control) Strategies

This is the ultimate goal of reliability-centered maintenance.

- Install Desiccant Breathers: This is a non-negotiable upgrade for critical equipment. These breathers strip moisture (and particles) from incoming air before entering the reservoir, stopping condensation at the source.

- Upgrade Seals: For critical rotating equipment, consider upgrading standard lip seals to more robust labyrinth or magnetic face seals that provide better protection against water ingress.

- Implement Best Practices: Enforce strict storage and handling procedures for all new lubricants. Use dedicated, sealed transfer equipment (like filter carts and sealed containers) to move oil from storage to the machine.

Conclusion: From Reactive to Proactive

Water is an active and persistent threat to asset reliability. Focus on water exclusion. Invest in desiccant breathers. Upgrade seals. Enforce proper storage and handling procedures. A clean, cool, and dry lubricant is the foundation of a reliable machine. By controlling water, you are directly controlling your equipment's health, reducing downtime, and lowering long-term maintenance costs. It is more costly to remove water than to exclude the water. "An ounce of prevention is worth a pound of cure" - Benjamin Franklin. Contact MRT Laboratories and one of our STLE or ICML certified professionals would be happy to assist you. We are ready to help you achieve your goals of reduced downtime and unexpected, expensive repairs.